If your organization handles office cleaning in-house, does your cleaning team have the necessary training to properly sanitize all the surfaces in your office? Although sanitizing and disinfecting are defined as different practices, they often go hand-in-hand. More importantly, there are right ways to do things if cleaners are hoping to truly sanitize a surface.

Below are some industry best practices for sanitizing office surfaces. As you read, bear in mind the main distinction between sanitizing and disinfecting: sanitizing is designed to both surface-clean and remove bacteria. Disinfecting goes one step further by eliminating viruses. Note that chemicals designed only to sanitize may not be effective against viruses.

Always Surface Clean First

Because sanitizing and disinfecting both involve germs that the naked eye cannot see, it is wise to make sure nothing hinders the sanitizing process. So surface cleaning should be performed before any sanitizing or disinfecting.

The idea here is to remove dirt and grime so it is out of the way. Once a surface is free of those larger particles, a sanitizing spray can reach the targeted bacteria more easily. It can kill those bacteria and be wiped away.

It is possible to surface clean and disinfect at the same time. And in some cases, doing so is appropriate. But in especially dirty environments, it’s always best to surface-clean before sanitizing or disinfecting.

Target High-Touch Areas

The biggest risk for spreading germs in an office environment is the high-touch surfaces workers make contact with on a regular basis. High-touch surfaces include computer keyboards and mice, phones, shared office equipment, desks, door handles, and light switches.

A sanitizing strategy should prioritize high-touch areas. By the same token, low-touch surfaces are lower on the priority list. If cleaners have time, they should still sanitize such surfaces.

Use EPA-Registered Disinfectants

Any cleaning chemical manufacturer can claim that its products sanitize and disinfect. But claims do not always equal reality. Therefore, industry best practices dictate using only EPA-registered disinfectants. Registration ensures that a cleaning chemical meets federal standards for disinfecting surfaces.

Common examples include:

- Chlorine bleach

- Isopropyl alcohol

- Hydrogen peroxide

Chemicals containing quaternary ammonium are also a pretty safe bet. In every case, it is important that cleaners follow manufacturer instructions printed on product labels.

Utilize Proper Techniques

Even the most effective cleaning chemicals don’t work as well as they should when cleaners use improper techniques. Therefore, industry best practices dictate proper techniques, including one direction cleaning. One direction cleaning involves wiping a surface in one direction only. This reduces recontamination that would occur if a cleaner wiped in multiple directions.

Sanitize on a Regular Schedule

Sanitizing is maximized when it is done on a regular schedule. How often should cleaning crews sanitize? That depends on the surface and traffic. High-touch surfaces should be sanitized at least once daily. High-traffic areas, like restrooms, might need sanitizing multiple times per day. In addition, extra sanitizing is a good idea during outbreaks of illness.

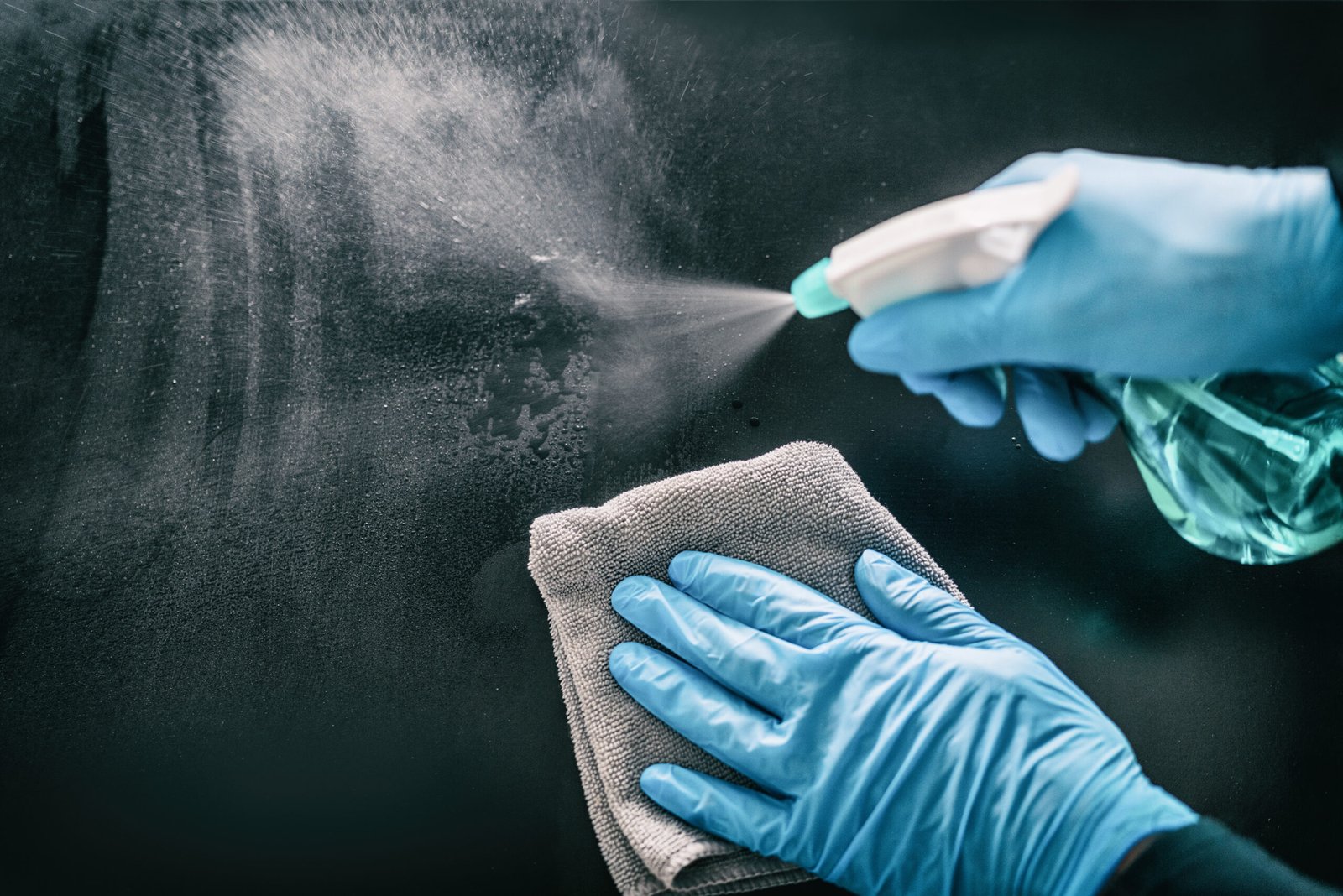

Utilize Personal Protective Equipment

Finally, best practices dictate that cleaning crews make use of personal protective equipment (PPE). At the very least, rubber gloves and eye protection are a good idea. Some cleaning chemicals warrant using a mask to protect against respiratory problems.

The goal of sanitizing is to kill bacteria that could otherwise make people sick. It is an intermediate step between surface cleaning and disinfecting. To sanitize is to promote a healthier and safer work environment. Utilizing industry best practices guarantees the best possible results. If your in-house cleaning crew is tasked with sanitizing the office, be sure they are doing things right.